Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

In the last few months a headline has been on everyone’s lips: the global electric‑vehicle (EV) market has broken past expectations, with sales in 2024 climbing over 35 % year‑on‑year. Major automakers—from Tesla to Hyundai, from Toyota’s new brand of hybrids to Ford’s aggressive battery‑electric line‑up—are racing to meet unprecedented demand. Behind the sleek bodies and buzzing dashboards lies an equally complex mechanical story: how power moves from a battery to a wheel efficiently, reliably, and quietly. The unsung hero of this process is the gear motor, often simply called a reducer motor, a compact device that transforms electric drive‑torque into precise, responsive motion.

The swift rise of EVs is not just an industry story; it is a societal shift toward cleaner, more efficient mobility. This backdrop presses on every component supplier, and gear motors, despite being a small part of the supply chain, are experiencing a surge in demand, development and strategic importance.

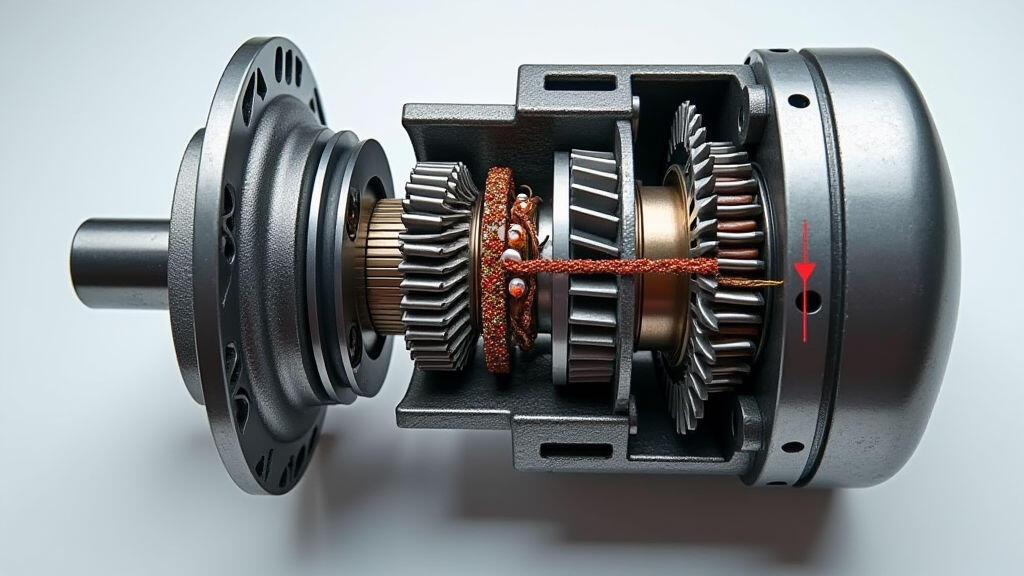

Electric cars rely on electric motors for propulsion. The wheel‑moving mechanism needs to be lightweight, extremely efficient, and compact—yet capable of delivering the high torque required for rapid acceleration. Here the gear motor steps in. A gear motor combines a motor’s electromagnetic action with a gear train inside a single housing, providing a reduced output speed and increased torque. This compactness and performance make it an ideal choice for modern EV drivetrains.

Most contemporary EVs feature either single‑speed gear motors in front‑wheel drivetrains or dual‑motor setups for all‑wheel drive. The gear motor’s internal gear ratio is carefully engineered for the vehicle’s size, intended power output, and driving conditions. A 30:1 gear ratio, for example, can swell a motor’s low rpm torque from 200 Nm to 6000 Nm—sufficient for a smooth, silent start while still supporting sporty torque when the accelerator is pressed deeply.

Additionally, modern gear motors are built with brushless, high‑efficiency designs that reduce energy waste, improve battery life, and therefore extend vehicle range—a key selling point in the current market. Because each gram of weight matters, gear motors also often feature lightweight housings and magnetic materials that keep the drivetrain as light as possible.

According to data from Statista and Grand View Research, the global market for automotive gear motors is expected to grow at a CAGR of 6.5 % from 2024 to 2030. The growth is directly tied to the adoption of EVs and electric industrial vehicles. In many regions, governments have introduced incentives—subsidies for EV purchase, stricter emissions regulations, and investment in charging infrastructure—all of which accelerate production and therefore gear motor demand.

For manufacturers, the use of navigational smart sensors and autonomous driving software demands high precision from the drivetrain. Gear motors provide the constant, high-accuracy torque control required for lane‑keeping and rapid evasive maneuvers in self‑driving scenarios, combining electronic speed regulation with magnetic armature control.

While semiconductors remain the headline of supply constraints, gear motors help soften the blows. Many gear motors use a small number of electronic components—mainly power inverters that can be sourced from diversified suppliers. Their mechanical nature allows them to be manufactured with fewer iterations, reducing lead time. The result? Auto makers can keep assembly lines running even as the chip supply remains fickle.

Companies worldwide, from small specialty German suppliers to large Asian OEM supporters, are expanding capacity. Joint ventures between motor makers and battery manufacturers—a synergy that integrates drive‑system design directly into battery architecture—are becoming common. These collaborations reduce component heat output, facilitate thermal management, and lead to better integration across the entire vehicle architecture.

The surge in EV sales is spurring gear motor innovation in several domains:

These innovations are not only applied to passenger cars. The rise of electric buses, freight trucks, and even autonomous delivery robots has expanded the scope of gear motor use, making them indispensable tools for the rapidly evolving industrial automation landscape.

In early 2024, German manufacturer Stephan Motors unveiled a new 2‑stage, brushless, toothed gear motor designed for 70 kW of torque output. Engineers highlighted its 99.8 % efficiency rating, achieved through advanced magnetic circuit design. The motor was rigorously tested on a modified Tesla Model 3 chassis and demonstrated a 4 % increase in range—a notable figure in EV markets where every percentage point matters.

Stephan’s partnership with a leading EV startup illustrates a trend: gear motor providers are customizing turbo‑drive solutions for very specific vehicle types, shifting from a generic “one‑size‑fits‑all” approach to advanced, vehicle‑specific engineering.

The 2024 mobility wave—a surge in EV sales, stricter emissions standards, and the thrust toward autonomous systems—is rewriting the rules of drivetrain design. Gear motors sit at the crossroads, translating electric power into torque in a manner that is both robust and refinement‑tyd. Their compactness, efficiency, and reliability provide manufacturers with the mechanical backbone needed to deliver high‑performance, eco‑friendly vehicles.

Going forward, the synergy between gear motor innovation and electric drive technology will keep pushing the envelope of mobility. Each new generation of motors brings smaller footprints, sharper precision, and better energy efficiency, factoring directly into longer battery ranges and smoother drives. For consumers, this translates to quieter cars that feel more responsive. For the industry, it translates into a strong, resilient supply chain that can withstand future shocks.

In the fast‑moving arena of clean transportation, gear motors may not grab headlines, but they physically empower the vehicles that are propelling society toward a greener, smarter future. Their quiet efficiency will continue to be a cornerstone of that progress.

Leave A Reply

Your email address will not be published. Required fiels are marked